One views the industrial Internet of Things (IoT) as billions of sensors do get connected into the intelligent systems that distract from its true role, which is digital transformation.

2 reasons manufacturers invest in IoT

- The first reason big companies to invest in IoT is they do get concerned about being digitally disrupted.

- The second reason is the company’s slow growth and its need for increased productivity.

Over a period of 40 years, SAP has indeed been the beneficiary of the last wave of manufacturing automation productivity.

SAP has indeed the largest share of the enterprise resource planning (ERP) market, with one-third of discrete and process manufacturers to make use of their software to plan and operate production. SAP directly, or rather indirectly through its implementation partners, does influence every industry.

SAP’s vision for IoT in manufacturing

Collaboration and networks will rather affect the industry borders thus making the respective companies work closer together. This implies more data sharing.

New technologies as new business models

The focus has been upon ERP and industrial automation thus increasing the efficiency of individual manufacturing plant by manufacturing plant — processes, inventory, equipment and people. The new business models are enabled by new technologies that include IoT, blockchain and machine learning.

Customization

This new type of manufacturing does combine the flexibility as well as the personalized approach of custom-made products with the low unit costs associated with mass production. For example, consumers can order customized Nike shoes and Motorola smartphones. The components are 3D-printed.

Service-oriented business models

In service-oriented business models, the machine is rather sold as a service with recurring revenue. It also does match the customer’s cost with use, thus moving the expenditure from the capital budget to the expense budget.

SAP’s IoT transformation: professional services, partners and product investments

SAP has no doubt thousands of customer and partner contact points in order to abstract the features of new IoT products.

IoT design thinking

SAP has also applied its design thinking methodology to IoT. Its professional services team does offer design thinking services, thus leading customers in multidisciplinary teams to identify, choose and implement first projects.

Leonardo IoT platform combining business and operational data:

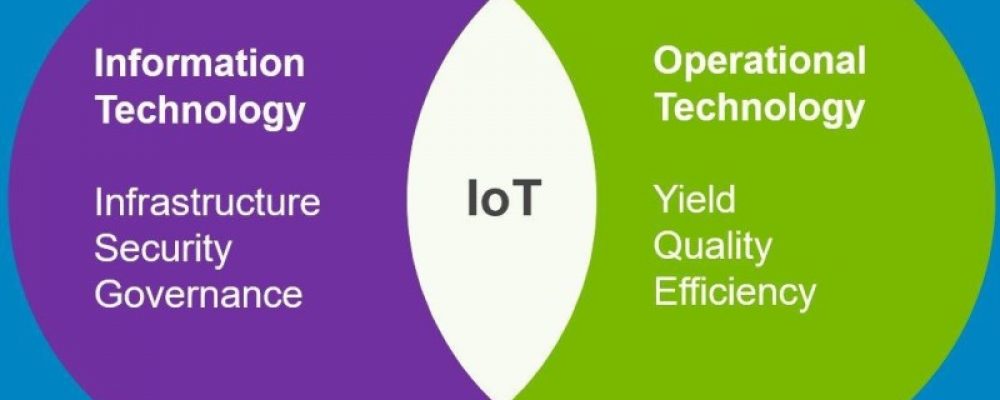

SAP’s partners and customers are also making use of the Leonardo IoT platform in order to build applications for industry-specific solutions, thus combining business as well as operational data to enable new business models

Product investments to remove IoT obstacles

SAP Leonardo IoT Bridge does point out to how customer prototypes are captured by SAP as a competitive advantage.

The Plat. One IoT platform, which SAP did acquire in 2016 does alleviate the challenges of interfacing as well as managing sensors that do feed operational data into business systems and also analyze the data.

SAP has much to contribute indeed and has become rather an indispensable tool for business growth and development. It has made varied contributions in the business arena and will continue to do so even in the future.